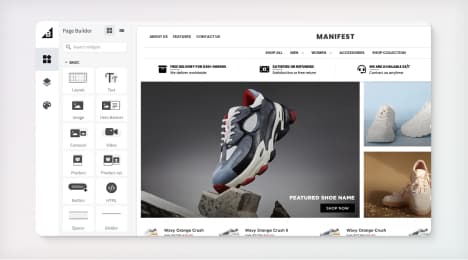

Watch Our Product Tour

See how BigCommerce helps you build and manage your online store with ease.

- Ecommerce Insights

6 Key Steps to Launch Your Online Store

Explore our Launch Foundations series to get your BigCommerce store up and running quickly.

BigCommerce helps growing businesses, enterprise brands, and everything in-between sell more online.

Why Inventory Efficiency is Critical for Ecommerce Success?

Your inventory is one of your most valuable assets; it’s also one of the most expensive.

Depending on your stock lead times and how quickly you sell products, your inventory is a ticking time bomb, becoming worth less and costing you more each and every day.

This is why inventory efficiency is critical for ecommerce success and profitability. This article will help merchants understand what it is, how to measure inventory efficiency, and how to improve it.

What is inventory efficiency?

Inventory efficiency is how effectively you use your inventory to balance customer demand and warehouse overheads. It’s about having the right products, in the right quantities, at the right time, as efficiently and cost-effectively as possible.

Good inventory efficiency means that you always have enough stock to meet demand, without units sitting in any warehouse for too long. That way, you reduce your operational costs while avoiding the risk of price declines and product obsolescence.

Poor inventory efficiency is the opposite. When merchants have poor inventory efficiency, they tend to regularly go out-of-stock, which hurts their metrics, or they have too much excess inventory that racks up storage fees and can even decline in price as items age.

The importance of inventory efficiency for ecommerce

Research shows that good inventory efficiency leads to higher business performance, and this is for many reasons.

1.Meeting customer demand

Inventory efficiency ensures you have enough products to meet demand, and you never sell out or oversell. Meeting customer demand is essential for attracting, converting, and retaining customers. This is especially true during peak retail periods like the upcoming holiday season, where your floor has essentially doubled based on what we’ve seen so far in 2020.

2. Maximizing profits

Good inventory efficiency reduces the time stock spends in the warehouse, decreasing operational costs (such as storage fees) and minimizing the risk of products depreciating from becoming out of season, out of trend, or expired. This increases profits, giving you more money to invest in business growth.

3. Sales and finance

Inventory efficiency is a critical business metric reflected in your accounts’ current assets and gross profit income statements. These figures are essential when applying for ecommerce financing, looking to sell your business, or using cash flow to expand into new product lines.

4. Business efficiency

Inventory efficiency data gives you insight into product performance and your ability to meet demand, and inventory efficiency tools facilitate stock checks, listing updates, and order fulfillment. Together, these increase your overall business efficiency, helping you invest time and capital wisely.

How to measure inventory efficiency

So, how do you know if you have good inventory efficiency? Measuring your inventory efficiency is more than sticking your finger in the air or a general awareness that you regularly run out of stock or don’t have enough storage space.

Instead, there are two important calculations:

1. Inventory turnover ratio

Your inventory turnover ratio is the number of times inventory sells during a given period.

Cost of goods sold / Average inventory*

*(inventory at the start of a period + (inventory at the end of a period) / 2)

A low inventory turnover ratio indicates poor inventory efficiency, which could be caused by overstocking, out of trend products, no market demand, or underperforming marketing.

A high inventory turnover ratio may also signal poor inventory efficiency, with inadequate stock levels to meet customer demand. It’s all about striking that balance.

2. Inventory conversion ratio

Your inventory conversion ratio is the number of days in a year it takes to sell inventory.

365 days / inventory turnover ratio

A high inventory conversion ratio means that your products are spending too long in your warehouse before being sold - taking up valuable space and squeezing your profit margins.

A low inventory conversion ratio demonstrates good inventory efficiency, but it’s essential to ensure that you hold enough stock to meet requirements. Again, it’s about that balance.

How to improve inventory efficiency

While it might feel like you’re walking a tightrope of too much vs. too little stock, there are ways to improve inventory efficiency without falling.

1. Stay attuned to market demand

Historical and market data are great for predicting customer demand when sourcing and ordering products to increase stock efficiency. However, it’s important to regularly calculate and forecast demand to keep your predictions in-line with current trends. This is known as dynamic inventory control.

For example, just because hand sanitizer was hugely popular in March 2020 doesn’t mean you need the same stock levels every March following (at least, we hope not).

Further reading: How to plan your inventory cycles

2. Negotiate MOQ

Minimum order quantities (MOQ) can hamper your inventory efficiency by requiring you to order more stock than you need. This stock then sits in your warehouse, taking up space and depreciating.

While you might feel you have little bargaining power, there are ways to navigate minimum order quantities and negotiate better deals with your suppliers.

3. Undertake inventory analysis

Running inventory analysis quarterly (or more often) gives you insight into stock levels and performance over time. Use this information to conduct an ABC analysis to classify stock according to:

The 20% of SKUs contributing to 80% of revenue.

The 30% of SKUs contributing to 15% of revenue.

The 50% of SKUs contributing to 5% of revenue.

Then invest your warehouse space and business capital accordingly, to increase your inventory efficiency. Any products falling outside of your ABC classification, due to low sales, you can reduce, place in flash sales, or destroy.

4. Use inventory management software

Inventory management software is the elixir of inventory efficiency. By using (or partnering with a fulfillment partner that uses) a suitable inventory management system, you gain an accurate overview of real-time stock data.

Use this information to undertake inventory analysis and help your fulfillment team pack orders to enhance inventory efficiency (e.g., first in-first out).

5. Communicate with your suppliers

Regularly communicate with suppliers and pay attention to their performance and stock levels. If there’s anything that 2020 has taught us, it’s that your inventory efficiency relies heavily on your supplier’s ability to deliver.

Tip: Diversify your supply chain where possible, using manufacturers based in different countries, using different supply routes.

6. Use adaptive storage solutions

If you run an in-house fulfillment operation using your own warehouses, sometimes it feels necessary to fill that space with stock because you’re paying all. However, the more stock you have sitting around, the more likely this stock will depreciate by falling out of season or expiring.

By partnering with an outsourced fulfillment company like Deliverr, you pay per cubic foot per month - allowing your space (and costs) to adapt to your customer demand.

Tip: Compare fulfillment rates using our ecommerce fulfillment calculator

7. Use an all-inclusive multi-channel fulfillment strategy

When you use a fulfillment partner that can handle orders across channels, it means you don’t have to send units into multiple different networks. For example, Deliverr merchants only need to send their units into Deliverr and can fulfill across marketplaces and their own stores, including, most recently, BigCommerce!

So you don’t have to worry about having slow-moving stock on one channel, selling out on another, and then needing to transfer inventory over from one fulfillment service to another. Deliverr fulfills from one central pool spread strategically across the USA to offer nationwide 2-day delivery while keeping your inventory systems lean and efficient.

Conclusion

Inventory efficiency is a hot topic of late, especially with businesses stockpiling in readiness for a second wave of the pandemic, a busy holiday season, and Brexit supply chain issues.

However, a full warehouse doesn’t equal a profitable warehouse. To secure ecommerce success, you must master inventory efficiency.

This is a guest post from Michael Krakaris. Michael is one of Forbes’ 30 Under 30 and the co-founder of Deliverr.

BigCommerce helps growing businesses, enterprise brands, and everything in-between sell more online.

Start growing your ecommerce business even faster.

High-volume or established business? Request a demo